How do you choose the right water pump when there are so many options? Petrol or diesel powered water pump? Electric or engine driven water pump? Firefighting or trash pump?

Don’t worry! This simple guide will fill you in on the common types of water pump, their applications and provide handy tips when selecting a product. So if you are considering water pumps for the first time, this article is for you.

There are three parts to this article:

Engine driven pump in a rollover frame

Part 1 – Pump types

Understanding the different types of pump available will help you work out the right pump for your application.

Engine driven

These are pumps driven by a combustion engine, powered by petrol or diesel. The two primary benefits are their portability and their ability to run independently of electricity supply. Water Master only makes this type of water pump. These pumps come in a variety of designs and sizes which we will go through below.

The last section of this article gives descriptions on different kinds of engine driven pumps

Electric powered

These come in a variety of sizes and designs to suit different purposes. These pumps can handle long running times and are often stationary units not intended for moving, such as providing a house or building with water pressure. While there are portable electric pumps, they obviously require access to electricity.

Jet

Jet pumps are designed to draw water from deep sources. They are typically used to draw water from bores, wells or sources much lower than the required destination. Many jet pumps are electrically driven, but engine driven models are available too.

Diaphragm

These pumps utilise a different mechanism than centrifugal pumps (read more about how pumps work here). They are designed to pump thick contents such as sewage, mud, or high solid containing water.

Stationary

Stationary pumps are often large and used for industrial or agricultural purposes. These are available as electric or diesel engine powered units. They are designed to move large quantities of water over long periods of time. (Welling & Crossley specialise in large pump engines and generators)

Part 2 – Pump applications

In Part 1 we had a look at the different kinds of water pump available. In this part we will look at some of the pump applications that are common for engine driven pumps.

Engine driven pump powering a home sprinkler system

Fire fighting

If you want a pump to use for home fire protection then it is essential to be able to power your pump without mains electricity. This means either a generator to power an electric pump, or the simpler solution of an engine powered fire fighting pump. Mains electricity is usually lost during a bushfire so it is very important to have an independently powered pump (read more about defending your property from bushfires).

Water transfer

Moving water from one place to another, whether it is from a dam, tank, construction site, building or some other source of water. The key considerations for this application are what level of pump performance you require (dealt with in the next section), and whether you need to move your pump from place to place. Our water transfer pumps are perfect for this application, with a wide range of sizes to suit your needs.

Dirty or debris filled water

If you are moving water that contains solids or debris then a trash pump is the ideal choice. They are designed to safely move water containing solids (up to certain sizes). This makes them well suited to dewatering worksites, and moving flood water.

Moving effluent or chemicals

Some chemicals, or contaminated water such as salt water and effluent can be damaging to certain pumps. A chemical resistant pump is made from materials that are corrosion resistant, such as plastic or stainless steel. If a chemical resistant pump is required, it is recommended to determine which materials are safe. These are commonly used for agricultural and industrial chemicals.

Providing water to buildings and gardens

The most common type of pump for these applications is an electric variant, with or without a jet. These pumps typically need to be able to run for long periods, and be ready on demand, so being powered by your electricity grid is ideal. There is a wide range of high quality options for this type of application.

Part 3 – Pump attributes

So you know about different pump types and some common pump uses, and you are interested in an engine driven pump, but there are still so many options. So how do you choose the right water pump? This section will tell you the most important pump attributes to consider when comparing products.

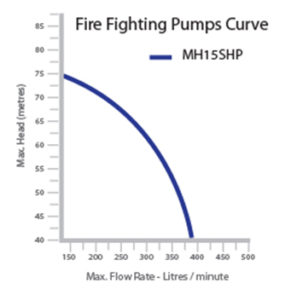

The pump curve shows pump head and flow characteristics

Water moving performance

The first and most important factor. Choose a pump that provides the performance you require. Water moving performance can be broken into three characteristics:

- Flow rate. This is measured in litres per minute (L/min). The higher the flow rate the more water you can move in a given time. You may require high flow rates for quick water transfer.

- Max head. This refers to how much vertical distance a pump can move water. The maximum head is an indicator of what a pump can achieve in suction height + uplift. For example, if you need to suck water up 5 metres and move it to a point 25 metres higher than the pump, then you will need a pump with a max head greater than 30 metres.

- Water pressure. Measured in PSI. Pressure is related to max head, as the pressure determines how far water can be moved. At a pumps maximum head, the water pressure will be zero. So it is important to consider how much pressure you need, and how far you need it from the pump. For firefighting pumps this is critical, and it is recommended that your pump has a maximum pressure over 100PSI. Multiplying max head by 1.42 will give you the maximum pressure.

Reliability and quality

There are many pumps available on the market, including very cheap examples. However if you want to know that it will be there when you need it, you should choose a trusted name that uses quality materials and components. Engine quality is important, as well as the materials the pump end is made from. Water Master firefighting and transfer pumps are made from high quality cast aluminium, our trash pumps are cast iron, and our chemical resistant pump is stainless steel. We only use premium brand engines. Read about our engine manufacturers here

Warranty

Choosing a brand which provides warranties is a good way to protect your purchase. Since Water Master is fully Australian operated, we provide easy, local contacts to help you with any warranty claims. All of our engine manufactures provide warranties (up to 3 years) and we offer a 2 year warranty for the rest of the pump.

Service and Support

Engine driven water pumps require maintenance to be kept in optimal running condition. They may also require replacement parts. Choosing a local brand with a large dealer/service network will make getting support easier. Water Master has multiple branches and is backed up by a nationwide dealer network of hundreds of stores. We are also completely Australian operated so you will always be able to speak to a local.

Fuel type

Pumps are available in either Petrol or Diesel. Petrol models are cheaper and usually come in more models. Diesel models are more fuel efficient and better suited to running for extended periods but are also more expensive. Diesel is also less flammable than petrol so can be safer.

Water Master Pump Options

- Firefighting Pumps – High pressure, moderate flow. A versatile pump that is useful for water transfer as well as defending homes from fire.

- Transfer Pumps – High flow, moderate pressure. These pumps are well suited to moving clean water. Available in a wide range of sizes.

- Trash Pumps – High flow, moderated pressure. These pumps offer the highest flow rates and are suitable for moving water that contains solids and debris.

If you would like further information please don’t hesitate to call us on 1300 833 513